Pulverized Coal Fired Steam Boilers is an industrial or utility boiler that generates thermal energy by burning pulverized coal (also known as powdered coal or coal dust since it is as fine as face powder in cosmetic makeup) that is blown into the firebox.

The basic idea of a firing system using pulverized fuel is to use the whole volume of the furnace for the combustion of solid fuels. Coal is ground to the size of a fine grain, mixed with air and burned in the flue gas flow. Biomass and other materials can also be added to the mixture. Coal contains mineral matter which is converted to ash during combustion. The ash is removed as bottom ash and fly ash. The bottom ash is removed at the furnace bottom.

This type of boiler dominates the electric power industry, providing steam to drive large turbines. Pulverized coal provides the thermal energy which produces about 50% of the world’s electric supply.

General Drawing of Pulverized Coal Fired Steam Boilers

Advantage Feature of Romiter Pulverized Coal Fired Steam Boilers

Based on the advanced pulverized coal fired technology, include the technology of pulverized coal feed, storage, transportation, combustion, ignition, flue gas cleaning, automatic control. Romiter company provide a whole set of new type industrial boiler technology for customer.

Adopting Pulverized coal concentrated preparation, precision pulverized coal making technology, fractional combustion, in-furnace desulphurization, shell type ( water tube) heat exchanger, high efficient bag house dust collector, flue gas desulphurization and high intelligent automatic control system, Bidragon realized the high efficient and clean emission target of industrial pulverize coal boiler.

- High efficiency and energy saving: burning rate of pulverized coal is beyond 98%, heating rate is beyond 88%,saving 35%-50% coal than the traditional coal fired boiler. Installing frequency converter on big power electric equipment saved much electric power obviously. Exhaust gas temperature is not more than 150℃.

- Environmental friendly: the pulverized coal burner adopts air staging and low-temperature combustion design, temperature distributing evenly to avoid much NOx by the part burning, lower pollutants emission intensity, pulverized coal ash no secondary pollution after being discharged from the close system. After the desulfurization and bag filter system, flue gas emission reach the following standard: ash≦30mg/Nm, SO2≦100MG/Nm3, NOx≦200mh/Nm3, which level meet station environment requirement and below station emission standard.

- High intelligent PLC or DCS control system: equipped with automatically control technology, boiler running, coal transporting, desulfurization dust removing, etc. is all controlled automatically, which ensures less smoker and better working environment. The system realizes instant start-stop function, cutting off the ignition source for 30 seconds and then run normally. Cutting off feed makes boiler stop. Automatic monitoring and parameter adjusting keeps it best running condition, meanwhile which decreases labor strength and disturb to boiler brought by human factor.

- Safe and reliable: the all system is running in closed system. Pneumatic coal transmission, centralized ash discharge, without ash and dust leakage, totally-enclosed powder process technology, rain and raise dust proof. Adopt high reliable program for ignition controller, which avoid detonation in furnace during ignition and provide flameout interlock protection. Electrostatic grounding and CO2 protection system, avoid spontaneous combustion of pulverized coal in coal storage tower, which provide safety coal storage and combustion safe.

- High performance cost ratio: High efficient and low operation cost will help customer withdraw equipment investment.

- Smaller floor space:Simple system flow, compact equipment layout, coal and slag don’t fall to the ground, without need of slag storage area, land-saving.

Pulverized Coal Boiler System Introduction

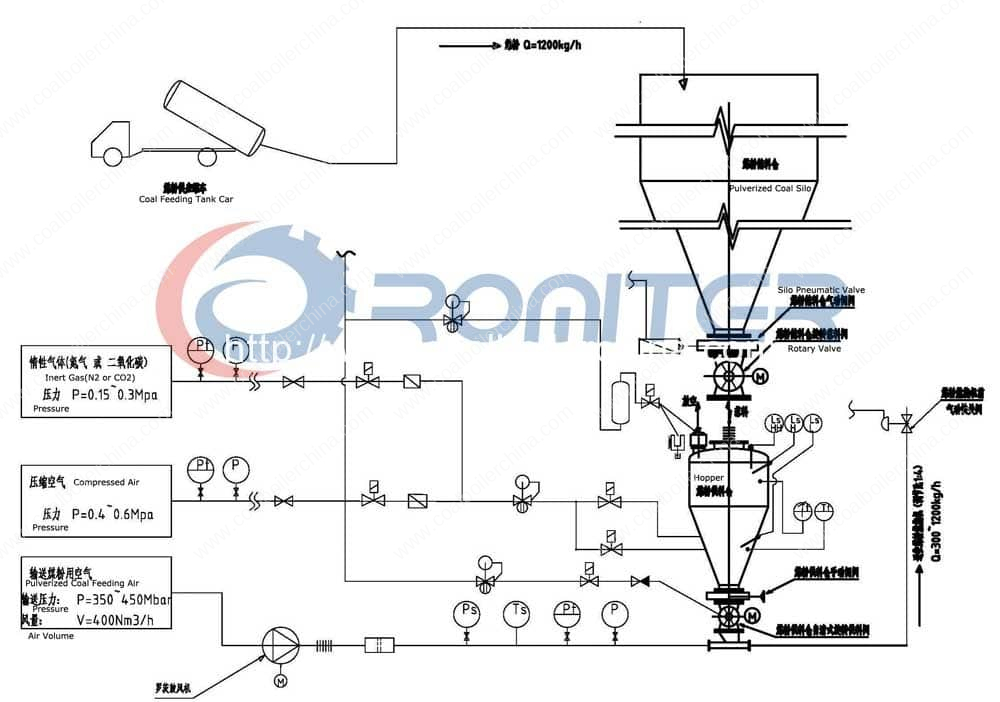

New type clean coal technology high efficient pulverized coal fired boiler mainly include pulverized coal bunker, rotary discharging valve, intermediate, pulverized coal bunker, screw feeder, primary air fan, secondary air fan, pulverized coal burner, boiler proper, economizer, bag house dust collector, induced draft fan, chimney,

Cost Comparasion Between Different Fuel Boiler

| No. | Item | Pulverized Coal Boiler | Chain Grate Coal Boiler | Coal Water Slurry Boiler | Heavy Oil Boiler | Natural Gas Boiler | |

| 1 | Thermal Efficiency | % | 90 | 60 | 83 | 90 | 90 |

| 2 | Fuel Price | RMB/t | 580 | 380 | 580 | 3100 | 5000 |

| 3 | Calorific Value | Kcal/Kg | 6000 | 5500 | 4400 | 10000 | 11500 |

| 4 | Fuel Consumption | Kg | 121 | 197 | 178 | 72 | 63 |

| 5 | Fuel Cost Price | RMB | 70 | 75 | 103 | 224 | 314 |

| 6 | Electricity Consumption | RMB | 4 | 6 | 9 | 4 | 2 |

| 7 | Worker Cost | RMB | 2 | 4 | 2 | 2 | 2 |

| 8 | Maintain Cost | RMB | 1 | 1 | 1 | 1 | 0 |

| 9 | Desulfuration Cost | RMB | 0 | 9 | 0 | 0 | 0 |

| 10 | Total Cost | RMB | 77 | 95 | 116 | 231 | 319 |

Upfront investment for a 10t boiler is about RMB1,000,000-1,500000 expensive than an coal fired boiler. but the operation cost for 10t pulverized coal boiler will be RMB1,700,000 cheaper than coal fired boiler, 89% of this RMB1,700,000 is saved from coal consumption reduction. This calculation is based 200 day work per year, 20 hours word per day. If the operation day and hour be longer, the saved money will be much more.

All in all, the high cost for buying an pulverized boiler will be saved from the coal consumption reduction in about half year.

Company Profile

Romiter Group has a large number of professional technique person and managerial personnel, who engated in design and manufacture boilers and pressure vessels, which makes Romiter can provide best quality products and best technical support.

Now, we concentrating on supply DZH Moving Grate Coal Fired Steam Boilers, DZL Chain Grate Coal Fired Steam Boilers, SZL Chain Grate Coal Fired Steam Boilers, YGL Coal Fired Thermal Oil Boilers, YLW Coal Fired Thermal Oil Heaters, Coal Fired Hot Air Furnace, Coal Fired Molten Salt Heaters, AAC Brick Steam Autoclave.

We are dedicated to global market and have exported boilers to more than twenty countries.We sincerely welcome all customers to contact and visit us to build long-term business relationship.